Conveyor

Conveyor

Expanding the scope of application and use of new technologies has led to the development of different functionalities and mechanisms for conveyors by engineers, but in general most conveyors use a central electric motor to drive a drum (a cylinder through which Friction moves the belt). Attached to it, on the other side, it makes a loop drill using a belt or chain loop that can be moved from one point to another by placing objects or materials. The Free-Flow Conveyor Roller is a special type of roller conveyor that, while the engine is running and running, has the ability to stop or slow down the rollers under the product. This function prevents the rollers from abrasing under the product's attack pallet or under the product itself.

This system is widely used in home appliance and other product lines.

Types of conveyors

Depending on the application or type of material carried by the conveyors, they are categorized by letters:

Carry packages and bags

It is commonly used in conveyor belt and drum mechanisms to carry packages and bags in various dimensions. It is mostly used in the food, pharmaceutical and petrochemical industries.

Using the flexible belt mechanism and angled rollers, the bulk material inside the trough formed by the load is loaded from the source and discharged at the destination. This Conveyor (Bulk Material) has a very wide range of applications and is widely used in the steel, petrochemical, cement and mining industries. The length of this type of conveyor can be very long and sometimes reaches kilometers.

Ground Conveyor

This type of conveyor is inserted into the ground to transfer the car or package or large boxes.

Air Conveyor

It is commonly used in the automotive industry to move car bodies and parts.

Lifting conveyor

This type of bucket Elevator, with spoons attached to a special type of chain, can move materials from surface (a) to surface (b). This conveyor is widely used in mining and steel industry.

Chain conveyor

It is a simple type of conveyor that is commonly used to carry pallets and is the floor.

Chain conveyors are designed and used in several ways as follows.

The chains are located under the floor of the production hall

1 – 1 In this method, when constructing the floor of the production hall, while the installation canal is considered, such as wind piping, etc., the chain wheel and the motor are placed in the required shape, and then the chain is moved in a certain direction by turning on the chain motor. According to Lay out, groove chains will be installed at the top of the routes.

The carriers carrying the product have vertical bars that are placed in the groove by the worker, so the chain can carry the carriage in the desired direction.

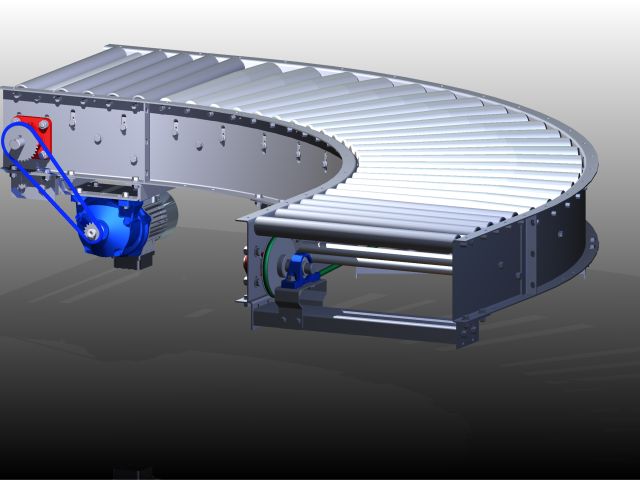

Conveyor Roller

Another type of conveyor is that the rollers can be moved by sliding on the rollers. This conveyor can be motorized or unmotorized. This conveyor can be motorized or unmotivated. The engine-free type is called gravity. The advanced version of this system is called Free-Flow Roller Conveyor, which has the following function.

Free-Flow Conveyor

The Free & Flow Roller Conveyor (Power & Flow Roller Conveyor) is a system in which the roller can be both a moveable (ie a drive) and a complete weed. In other words, the pallet roller moves the product carrier in a linear manner and continues to move until a predicted obstacle such as a stopper is activated. When the stopper is activated or any other obstacle is placed in front of the product carrier, the pallet movement stops. In this case, the free-flaw system plays its role, which means that the rollers in contact with the pallet are rounded up.

In this case, it is not possible to stop the palette containing the product in the middle of the road due to the smoothness of the movement path or ... and there is no problem in the production process. Also, the appropriate width designed for rollers creates more friction by creating more friction. Also, the appropriate distance between the upper surface of the roller and the lower surface of the pallet makes it impossible for the pallet to wear to the body. Of course, the side roller also plays a very important role in guiding the palette better. This system is mostly recommended for production lines where the product must be connected to electricity and on while moving.

Long Rollers Conveyor

The technical specifications of this system are the same as in the previous two systems, and the only difference is the replacement of long-range rollers instead of wide rollers. In this system, the product can be transferred without the need for a pallet.