Jig and Fixture

Jig is a tool for maintaining and locating workpieces, as well as guiding tools for a machining operation. In other words, a jig is a tool for guiding machining tools accurately. In fact, the main purpose of using jig is to machine or drill products in the production line accurately and without error.

Important points about jigs are:

Jigs are used in two-dimensional processes such as drilling, tapping or electrification.

There are many types from very light and simple to heavy and complex.

With Jig, there is no need to confuse the block, but the cost of building Jig may be higher.

Fixture

A fixture is a device for storing and placing a workpiece, except that it is not responsible for guiding the tool and is used to keep the workpiece in a certain position. A fixture is a device in which a workpiece is placed to be ready for machining.

Important points about fixtures are:

Fixers are usually attached to a machining table.

The use of gague blocks may be required.

They are very useful in milling processes.

The cost of producing fixtures is usually lower than jigs.

Jigs and fixtures

Both are used to reduce production time and error. But because the jigs are also responsible for guiding the instrument, special bushings or tabs are used in their production that the fixtures do not have.

Jig and fixture design

The factors that should be considered in designing a jig and fixture are as follows:

Check the workpiece

Recognition of clamps and loading and unloading

Study of tools and issues including vibration and strength

Calculate the tolerance and looseness between the jig and the workpiece

Consider the process of leaving the workpiece.

Safety issues for the operator , during production

Types of jigs

Planarity jig

Perforation

Tapping

Loop (ringular)

Box-shaped

Profile

Angular

Types of fixtures

Welding

Milling

Machinery

Assembling

Modular

Why use jigs and fixtures?

Reduce installation time before machining

Reduce operator training time

Increase the accuracy and quality of production

Increase production

Apart from these, Jig and Fixture also have the following disadvantages:

They corrode and wear out.

The cost of producing or reproducing them is high

Many materials are used to produce them and they are heavy.

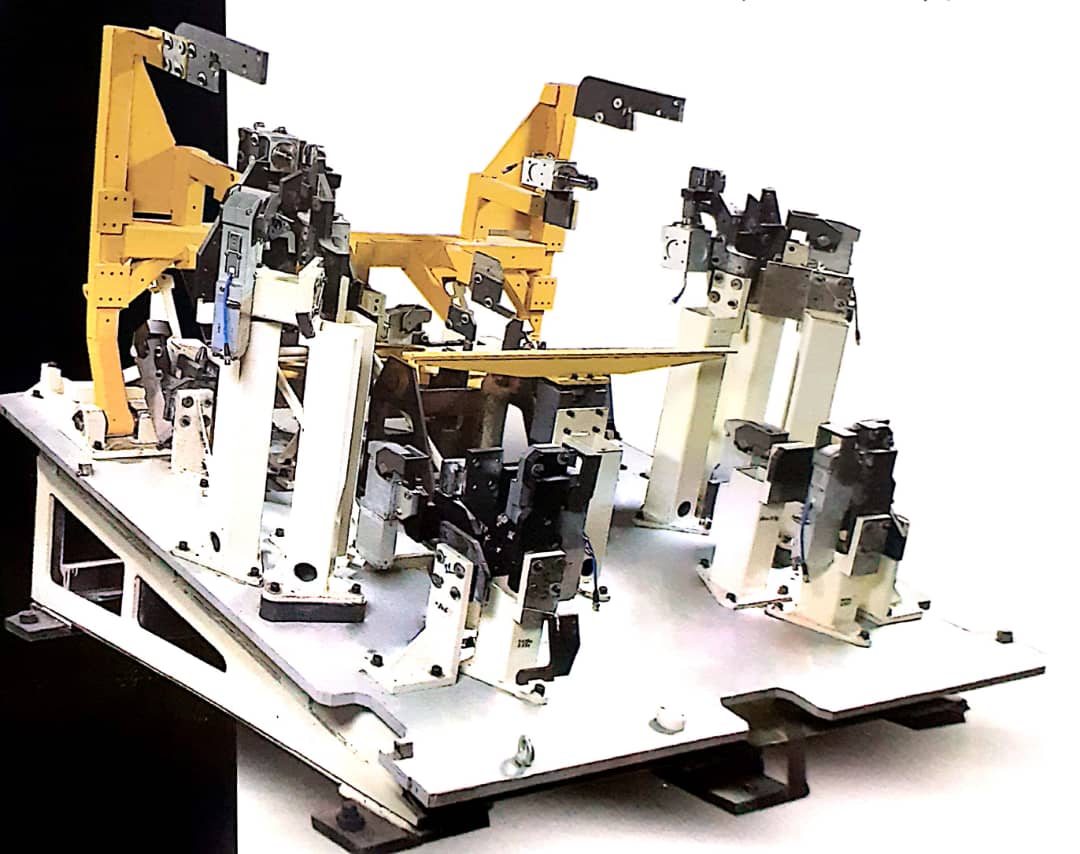

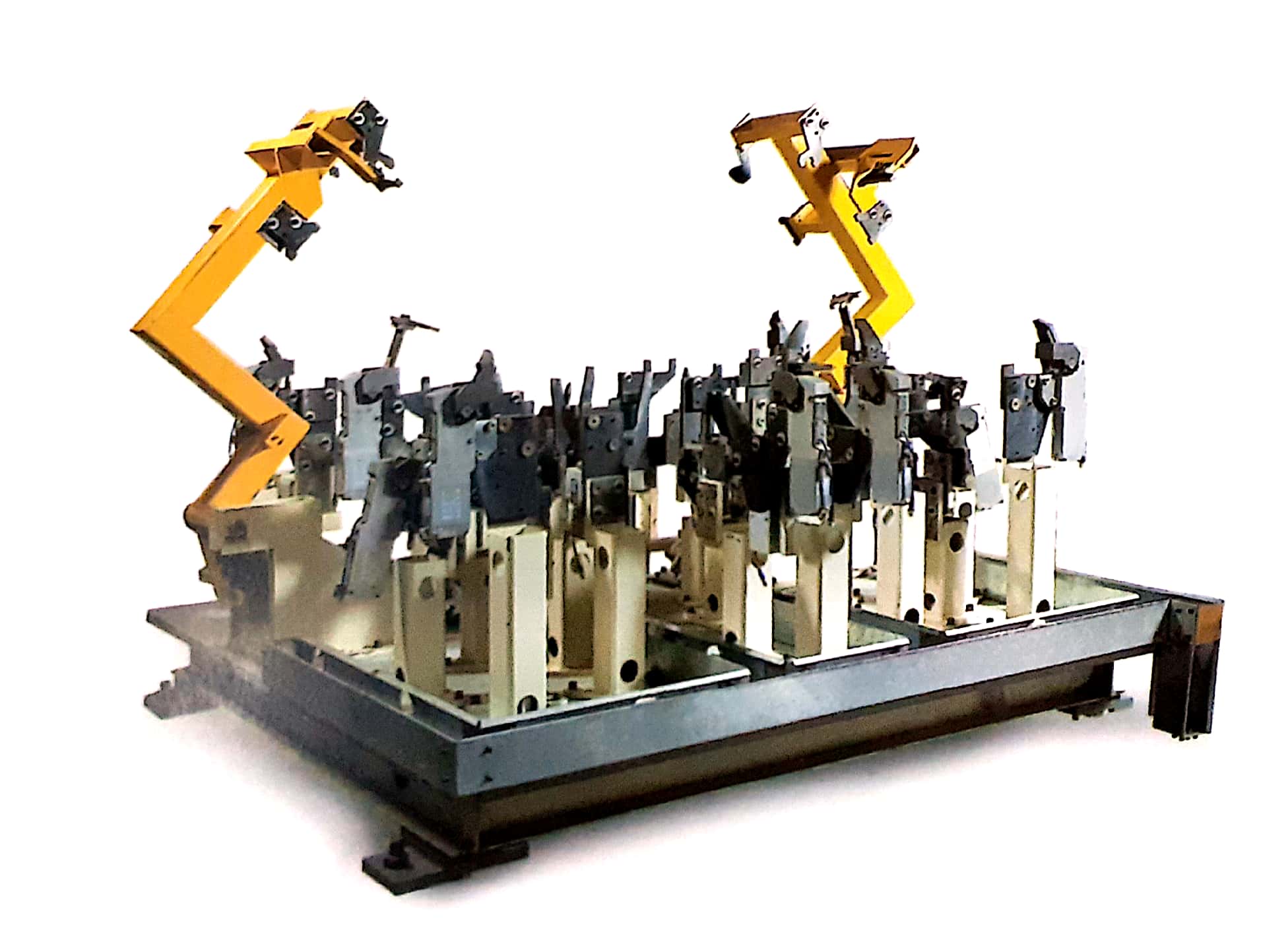

Uses of jig and fixtures

Manufacture of car parts

Inspection of products produced in production lines

Oil and gas and plumbing industries

Multi-axis milling

Materials which is used to make jigs and fixtures

Gray cast iron

Hardened steel

Carbide

Plastic

Teflon

Stainless steel

The high accuracy of automation products is the result of using up-to-date design and engineering software.

Examples of RADOX experiences in various industries, participation in projects such as:

IRANKHODRO company

Peugeot 405 production line fixtures

Samand limousine production line fixtures

Peugeot RD production line fixtures

Features of Peugeot 206 production line

Peugeot SD 206 production line fixtures

Peugeot L 90 production line fixtures

SAIPA Company:

Pride production line fixtures

Color line automation

Bahman Automotive Group:

Mazda 323 and mazda3 production line fixtures

Hepco Company:

Fixers for loader and grader production lines

SAPCO:

Peugeot chair production line checkboxes

Cement factories:

Machining jigs and several other industrial projects